Automatic Replenishment ~ Warehouse Management (WM) in SAP

This article is intended for SAP functional consultants to configure automatic replenishment of a particular storage type for transfer orders. Whenever the stock in a bin falls below the MIN value (predefined minimum quantity), it will trigger replenishment or transfer request (TR) which will in turn get converted into a transfer order, so that the workers in the warehouse can carry out the actual physical transfer of stock.

We have a provision of assigning a definite storage type from where the stock will be picked up for replenishment.

Step 1:

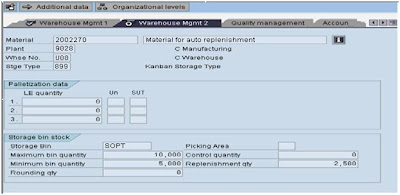

Material Master has to be maintained with Warehouse Views.

Under Warehouse Mgmt 2 Storage bin, Maximum bin Quantity, Minimum bin Quantity and Replenishment Quantity has to be maintained.

Configuration Changes:

Step 2:

Movement type 320 is copied from existing movement type 319 under Logistics Execution ->Warehouse management->Activities->Transfers->Define Movement Types.

Movement type 320 is configured as the following and saved. We can define SRC for the Source storage bin so that no interim storage bin is taken into consideration.

Step 3:

Replenishment Control is defined for the storage type under Logistics Execution ->Warehouse management->Activities->Transfers-> Define Replenishment Control for Storage Type and saved.

Dedicated printers can be set up under Logistics Execution ->Warehouse management->Activities->Define Print Control for a particular storage type and saved

Step 4:

One job needs to be scheduled for each report. The report jobnames are randomly defined:

Report

~~~~~~~

~~~~~~~

RLAUTA10

RLLNACH1

.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Hi Raj,

ReplyDeletethis looks good, thanks. I miss the last part however, it is not finished. My question is, can you make this work event triggered, so that replenishment happens directly when stock is taken out and below minimum?

Thanks Onno

Hi

ReplyDeleteI have been doing replans with lp21 and den lb10 to convert tr into to.

But suppose if we have stock for replanishment, is there any way datvwe can avoid those stocks.

I am usually clicking on to in foreground.

Thanks

Hello Raj,

ReplyDeleteI have question, if it is possible to use Replanishement WM functionality also for materials managed in HU-location.

I made short test, maintained material (WM views), created TR (LP21) and TO (LB11), but during TO confirmation I get error message and it is no possible to confirm it.

Thank you in advance for your answer!

Sana

A warehouse management system (WMS) is a key part of the supply chain and primarily aims to control the movement and storage of materials within a warehouse. survival warehouse food supplies

ReplyDelete

ReplyDeleteThat's really cool buddy.....Obviously the lady was logical.

SAP Consultants in London